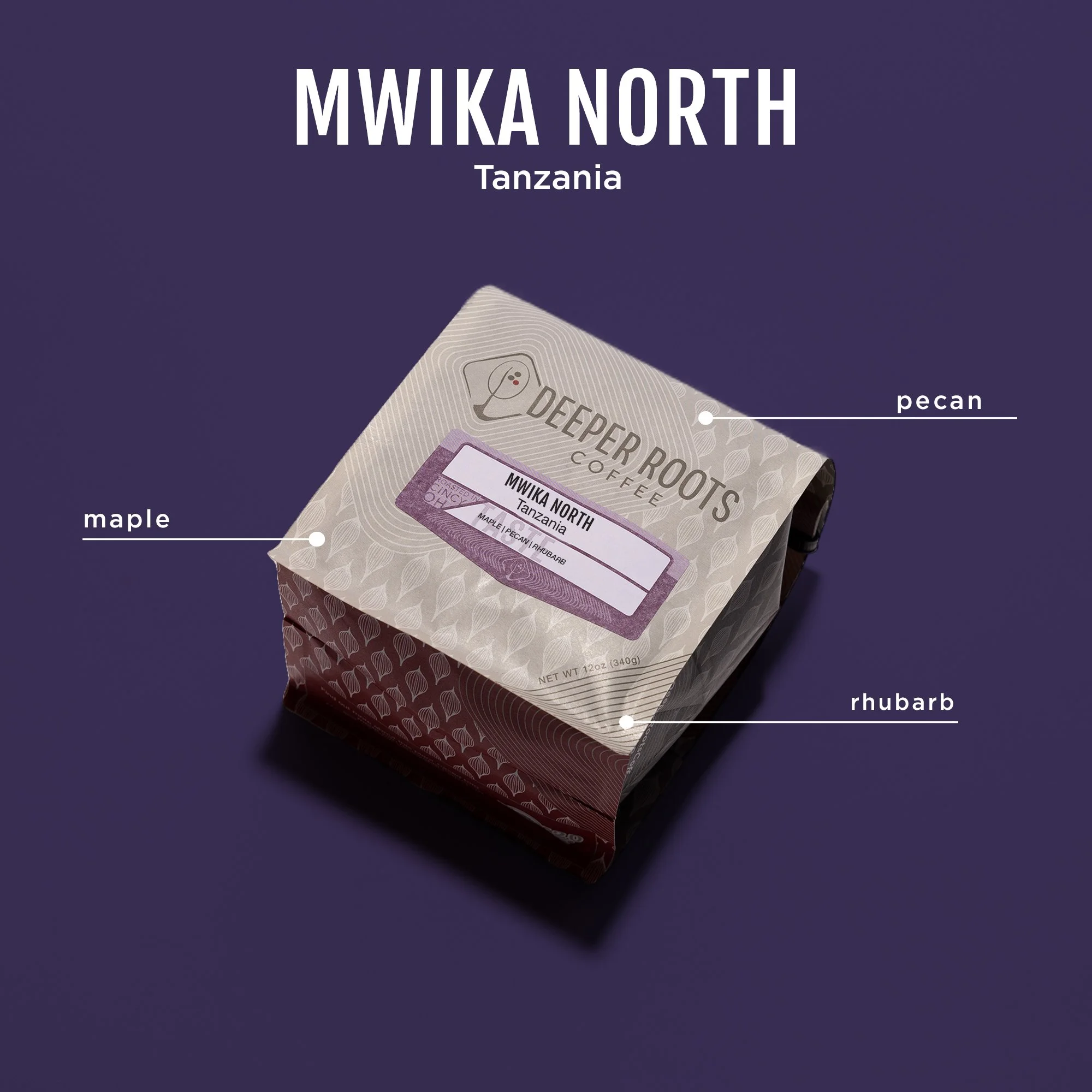

Mwika North | Tanzania

This coffee has become a mainstay on our offerings list and we’re thrilled with how it’s tasting this year. Maple sweetness with a notable nuttiness and a rhubarb acidity.

This coffee has become a mainstay on our offerings list and we’re thrilled with how it’s tasting this year. Maple sweetness with a notable nuttiness and a rhubarb acidity.

This coffee has become a mainstay on our offerings list and we’re thrilled with how it’s tasting this year. Maple sweetness with a notable nuttiness and a rhubarb acidity.

All of us here at DRC have been really looking forward to this year’s fresh crop Mwika North and it does NOT disappoint. It has always been a favorite of the team and we love sharing it with you all. This lot was processed using the Coffee Processing Unit (CPU or washing station) that is now operational after a decade of being unusable! One of our previous Community Giveback Projects helped get the CPU up and running and Mwika has been using it since the 2020 harvest. There are a couple of major benefits to this new, centralized processing. The CPU will bring a new level of consistency and quality control to Mwika North. Historically, farmers in the area had done all the de-pulping at their homes and brought coffee in parchment to Mwika North. Now, contributing farmers can put all their energy into growing & harvesting more efficiently, ensuring that only ripe cherries are being picked and brought for processing. All the de-pulping can now be done on site at Mwika North using the CPU. By centralizing and standardizing the de-pulping and processing at one location rather than many, they can better control and monitor the entire process, which gives us much higher levels of consistency and quality from cup to cup. The other benefit to this new system of processing is that the contributing farmers can now be more quickly paid for the cherry that they are selling to Mwika North. Simply put, less time spent by each contributing farmer getting their coffee to the processing facility, results in more timely payment for that coffee.

The wet mill was built over 15 years ago but never had the infrastructure to be able to run. After some input and funding from us and a mountain of work from Crop to Cup Coffee Importers and Taylor Wench Tanzania, Mwika did a trial run of coffee from their co-op members through the mill and the outcome was phenomenal. This year’s lot is a continuation of that work and was entirely processed through the CPU. We’re still working with issues locally to help Mwika fulfill their goal of running. ALL their coffee through the on-site wet mill. Farmers will get paid sooner, quality will go up and we were all able to play our small part state-side. Option 3: Win-win-win.

QUICK FACTS

Country/Region: Tanzania / Kilimanjaro

Farmer: 180 farmers from the Mwika AMCOS

Cultivar: Bourbon, Kent, and N39

Altitude: 1430-1530m

Processing: washed